For the castings that form the base of our machine bodies, we have consolidated our group’s capabilities to achieve in-house production, establishing an integrated manufacturing system that spans everything from wooden pattern design to component machining, painting, and final product assembly.

Leveraging the expertise cultivated throughout our manufacturing processes for development, we will continue to deliver even more superior products.

Wooden Pattern

Factory

Wooden patterns are essential for producing the castings that form the base of machine tools.

At OKAMOTO, we handle the design of these wooden patterns in-house, giving us the strength to manufacture rigid grinding machines from the ground up.

Casting Factory

We manufacture machine tools from castings. This enables us to improve quality, reduce costs, and shorten delivery times. We can also accommodate special requests for bases according to customer specifications.

Cost Reduction Initiatives

We view the pursuit of cost reduction and in-house production as our mission as a manufacturer and actively implement it. All our domestic and international manufacturing sites incorporate processing factories.

Automatic

painting system

We adopt an automated painting system using automatic conveyors to achieve labor savings. We maintain equipment capable of handling each individual part

Scraping

Technique

A scraping process is a process performed to reduce friction resistance on sliding surfaces, which are critical components of machine tools. We pass down scraping techniques from experienced employees to younger staff.

Craftsmanship

Even cutting-edge electronics technology has its limits. While we incorporate state-of-the-art equipment and achieve automated operation through CNC control, we also preserve the skilled craftsmanship of manual techniques known as ‘kissage’ for certain parts of the process.

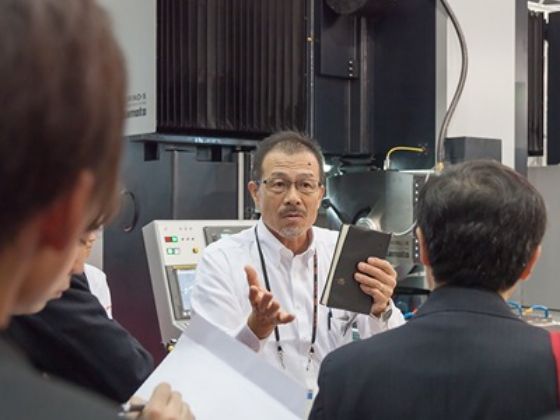

Experienced Sales Team

OKAMOTO has sales offices both domestically and internationally. At each location, we will propose machinery tailored to your specific processing needs.

Grinding process team

For customers requiring special processing, our test grinding team assists you. Experience the quality of OKAMOTO through actual grinding.

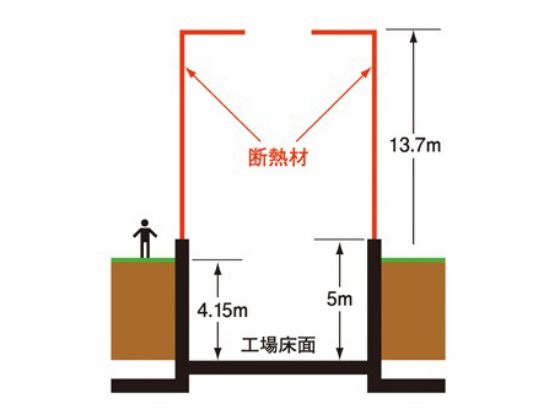

State-of-the-art factory

Our Annaka Factory features a semi-underground design with full air conditioning and dustproof, earthquake-resistant construction. Additionally, it boasts a constant-temperature factory and clean rooms capable of handling precision machining and assembly, providing an ideal working environment for manufacturing ultra-precision grinding machines and semiconductor-related equipment.

Machine

Assembly

We assemble custom-made machines tailored to each individual company and adopt a parts management system by just-in-time method.

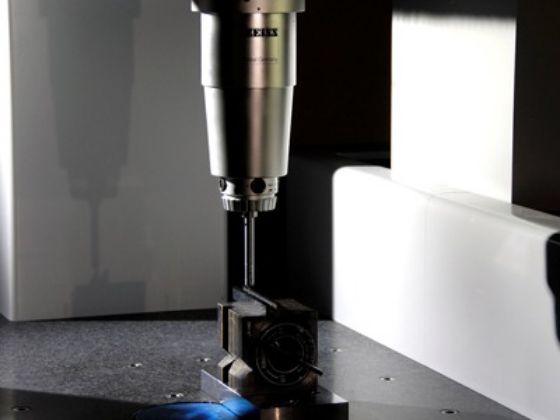

High-precision

measurement

The inspection room has ZYGO and ZEISS instrument.

We can comfirm production qualities in our factory.

Closely

follow up system

Okamoto posts servicemen around the world.

We are dedicated to acquiring technical skills daily to ensure we can handle regular inspections and machine maintenance after delivery.

Communication

with the Customers

We participate in and sponsor major large-scale exhibitions such as JIMTOF and SEMICON, as well as smaller regional exhibitions and private shows. Through these activities, we meticulously capture the diverse needs of our customers and strive to further enhance product quality.