Message from CEO

“Technology the Right Way – As a manufacturer with 90 years since establishment”

Okamoto was established more than 90 years ago as a manufacturer of gear grinding machines.

Thanks to the people who concerned, Okamoto became the “Total abrasive processing machine manufacturer”, is producing machine tools and semiconductor processing equipment , and is contributing to the high-quality and high-precision machining in the world aiming to the next-generation manufacturing.

Proud to be a manufacturer with visions and technology to see the “World”

Okamoto has had a global vision for 50 years. We established a manufacturing site of conventional machines in Singapore, a site with the integrated system from casting, parts manufacturing to assembling in Thailand, and other sales & service bases around the world.

Okamoto has earned the trust by Japanese and International customers for the technologies and quality which is accumulated in its long history.

Nearing to 100th anniversary, Okamoto will strive to further improve and develop our total technology together with the Okamoto group employees in the world, for the customers, employees, and societies.

Our motto is “Technology the Right Way.”

Our ideal goal is creating something beyond customers’ needs.

We will further challenge as a unique “total abrasive processing machine manufacturer” in the world.

We appreciate your warm support and frank opinions.

COMPANY PROFILE

[ Head Office / Annaka factory ]

2993 Gobara,Annaka,Gunma,379-0135 JAPAN

PRODUCTION PLACE

OKAMOTO (SINGAPORE) PTE, LTD.

OKAMOTO (THAI) CO.,LTD.

OKAMOTO (CHINA) CO.,LTD.

Company & products History

A 90-year tradition of craftsmanship in machine tool manufacturing,

passed down from generations of predecessors.

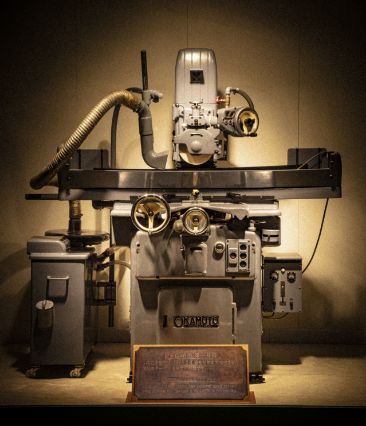

Kakusaburou Okamoto founded Okamoto Specialized Machine Tool Manufacturing Co., Ltd. as a privately owned business.

Developed Japan’s first gear grinding machine, the ASG-2 model.

The company changed its name and organization to Okamoto Machine Tool Works, Ltd.

and established its head office at 3-4 Ginza, Kyobashi-ku, Tokyo.

The Yokohama Factory began operations with the relocation of some of the equipment from the Yaguchi Factory, which was the main factory at the time, and the construction of new facilities.

Relocation of Tokyo Head Office to Kohoku Ward, Yokohama City.

The entire headquarters and Yokohama factory were requisitioned by the US military.

Market trading of our company’s shares was naturally suspended as a result of the above requisition.

Merged with Hosoda Machinery Co., Ltd.

Started manufacturing surface grinding machines.

Developed Japan’s first surface grinding machine, the PSG-6 model.

Developed the IGM series of internal grinding machines.

Developed Japan’s first peripheral blade slicing machine PSG3Ge type.

The requisition of Head Office and Yokohama Factory was fully lifted.

Establishment of development and production system for surface grinding machines and various other machine tools.

Listed on Tokyo Stock Exchange Second Section.

Developed the world’s first CNC surface and form grinding machine, the NFG-5 model.

Developed the OGM series of cylindrical grinding machines.

Established OKAMOTO CORPORATION as a sales company in Chicago, USA. (currently a consolidated subsidiary)

Spun off the gear division of the Hiroshima Plant and established Okamoto Gear Co., Ltd.

Established OKAMOTO (SINGAPORE) PTE LTD, the first local subsidiary to manufacture machine tools in Singapore (currently a consolidated subsidiary).

Started manufacturing machine tools in Singapore, the first in the country.

Developed the PRG series of rotary surface grinders.

Hiroshima Factory spun off to form Okamoto Machinery Co., Ltd., which is responsible for manufacturing small models.

Furthermore, Service division spun off to form Okamoto Giken Service Co., Ltd.

Established Sanyo Okamoto Co., Ltd. to handle sales in the Hiroshima area.

Annaka Factory construction was completed and begun operations.

Our affiliate Okamoto Giken Service Co., Ltd. changed its name to Giken Co., Ltd.

Yokohama Factory relocated and closed; Atsugi Factory opened in Atsugi City, Kanagawa Prefecture.

New Atsugi Factory construction was completed and begun operations.

Our subsidiaries Okamoto Machinery Co., Ltd., Okamoto Gear Co., Ltd., and Sanyo Okamoto Co., Ltd. merged to form a new company, Okamoto Machinery Co., Ltd. (currently a consolidated subsidiary).

Developed the best-selling PFG500 series of general-purpose grinding machines.

Established OKAMOTO (THAI) CO., LTD. in Thailand (currently a consolidated subsidiary)

Developed the best-selling PSG-DX series of general-purpose surface grinding machines.

The second phase of construction at the Annaka Factory was completed.

Acquired Nissho Co., Ltd. and made it a subsidiary.

Business alliance with US machine tool manufacturer.

Established OKAMOTO MACHINE TOOL EUROPE GmbH, a local subsidiary in Germany (currently a consolidated subsidiary)

Acquired Shibayama Machinery Co., Ltd. and made it a subsidiary.

Okamoto (Singapore) Pte, Ltd. obtains ISO 9002 certification.

(a first in the machine tool industry in Asia)

Established a branch office in Singapore as a sales and service base.

Merger with Shibayama Machinery Co., Ltd.

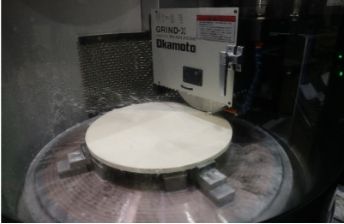

Establishment of Semiconductor Business Division.

Received the Technology Award from the Japan Society of Mechanical Engineers (JSME) for the development of a fully automatic vertical high-precision surface grinding machine.

Received the Technology Award from the Japan Society for Abrasive Technology (JSAT) for the development of a fully automatic high-precision, high-efficiency CMP device.

Sales of the best-selling PSG-DX series of general-purpose surface grinding machines exceeded 5,000 units.

Relocation of head office to Atsugi City, Kanagawa Prefecture (Atsugi Factory)

Establishment of a representative office in Shanghai, China.

Relocated main office to Annaka City, Gunma Prefecture (Annaka Factory)

Relocated head office to Kohoku Ward, Yokohama City.

Completion of clean room for testing and inspection of semiconductor-related equipment at Annaka Plant.

Completion of temperature-controlled processing and assembly booth at Annaka Plant.

Completion of new assembly plant at Okamoto (Thai) Co., Ltd.

Spindle room completed at Annaka Plant.

New casting plant completed at Okamoto (Thai) Co., Ltd.

(Combined production capacity of old and new plants became 1,800 tons per month)

Completion of the sheet metal and painting factory at Okamoto (Thai) Co., Ltd.

As equipment for the Annaka Factory,

the world’s largest ultra-precision double column type surface grinding machine UDG10035NC with a hydrostatic guideway system has been completed.

Integrated Singapore branch into Okamoto (Singapore) Pte Ltd.

iQ software developed to convert surface grinding know-how into software. Development of machines equipped with iQ software.

Development of PSG-CHLi series double column type CNC precision surface grinding machines to meet the demand for high precision and high efficiency in large workpieces such as progressive dies.

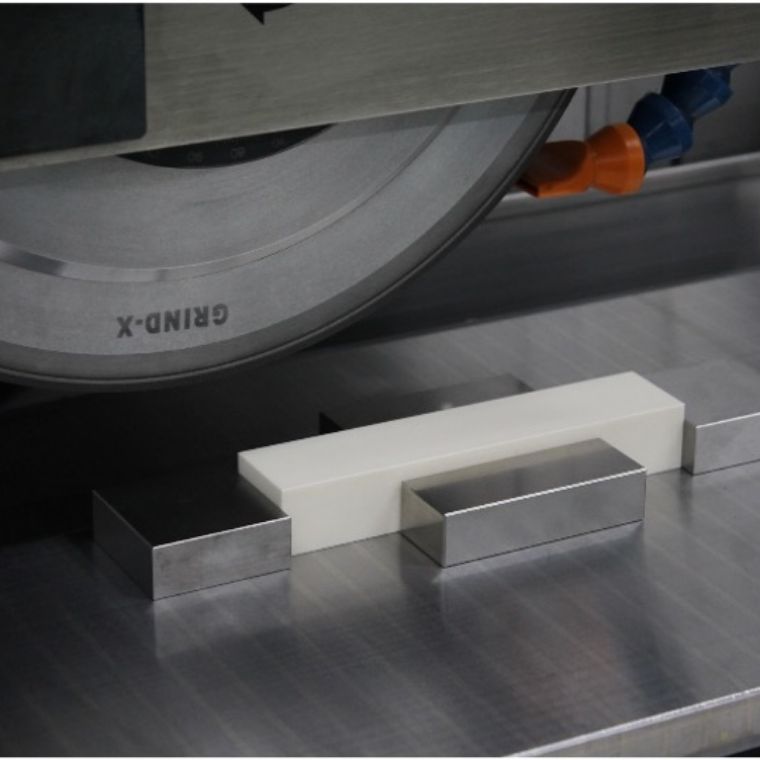

In order to meet the demand for micro-forming of small parts,

we have developed the UPZ210LiⅡ ultra-precision forming grinding machine driven by a linear motor.

Relocation of head office to Annaka City, Gunma Prefecture (Annaka Factory)

A new Machinery Division is established at Okamoto Engineering (Changzhou) Co., Ltd., a Chinese subsidiary of Okamoto Engineering Co., Ltd., and the Shanghai Representative Office is transferred to that division (currently a consolidated subsidiary).

Our subsidiaries Giken Co., Ltd. and Nissho Co., Ltd. merged to form a new company, Giken Co., Ltd. (currently a consolidated subsidiary).

Development of UGM360NC CNC Precision Universal Cylindrical Grinding Machine.

, which was annouced at JIMTOF2014, the 28th Japan International Machine Tool Fair.

Held the OPENHOUSE 2015 exhibition to commemorate the 80th anniversary of the company’s founding.

Announced “Grinding Innovation” as the theme for the 80th anniversary.

Developed the HPG500NC series of high-precision forming grinding machines.

Developed the SELF fully automatic surface grinding system.

Developed PSG-SA1 series precision surface grinding machines.

Developed the IGM15NⅢ-2B precision internal grinding machine.

Developed the UDG-Li series of double column type CNC precision surface grinding machines.

Launched the Quick Touch on-machine measurement system.

The ASG-2 type spur gear grinding machine, a collection of the Museum of Industrial Technology, Nippon Institute of Technology, was listed in “Mechanical Engineering Heritage” No.106 accredited by the Japan Society of Mechanical Engineers (JSME).

Established OKAMOTO INDIA PRIVATE LIMITED as a sales company in India.

Transition to the Tokyo Stock Exchange Standard Market

Three newly developed models exhibited at JIMTOF 2022

・CNC precision surface grinding machine PSG126CA-iQ

・Vertical rotary surface grinding machine VRG-DX series

・Grinding center UGM64GC

Acquired all shares of Daiwa Koki Co., Ltd. in Miyakonojo City, Miyazaki Prefecture, making it a wholly owned subsidiary (currently a consolidated subsidiary).

Acquired the surface grinding machine manufacturing and sales business from Nikko Co., Ltd. in Nagaoka City, Niigata Prefecture, and established NICCO Co., Ltd., a new wholly owned subsidiary of our company.

Established the Kyushu Technical Support Center to expand our semiconductor service base.

Received the SUMCO Supplier Award.

Concluded a capital and business alliance agreement with Mitsui & Co., Ltd. and implemented a third-party allocation of new shares to Mitsui & Co., Ltd.

Fully automatic grinding equipment for through-Si via wafer was recognized as a successful development by the Japan Science and Technology Agency.

Environmental policy

- We will advance the development of superior technologies and products for the conservation of the global environment, aiming to provide superior products and services.

- Through efficiency improvements, leveling, and waste reduction activities in our business operations, we strive to reduce energy consumption, waste, and other environmental impacts, thereby minimizing our environmental footprint and protecting biodiversity and ecosystems.

- We comply with environmental laws and regulations, as well as other requirements to which the organization subscribes.

- We will establish environmental policies and objectives, and strive for continuous improvement of our environmental management system to enhance our environmental performance.

Establishment date: January 9, 2018

Chief Enviromental Officer: Gyo Ito

The following Scope: The design, development, manufacture of machine tools and semiconductor-related equipment.

Established a world-class quality management system.

Three domestic and overseas factories have obtained ISO 9001 certification.

Our Annaka Plant, a pioneer in fully air-conditioned factories utilizing a semi-basement structure, along with our Thailand and Singapore plants, have all received high praise for their facility environments.

We have rigorously pursued quality management. In 1994, our Singapore factory became the first in the Asian machine tool industry to obtain ISO 9002 certification.Subsequently, our Annaka factory obtained ISO 9001 certification in 2004, followed by our Thailand factory in 2005, establishing a quality assurance system based on international standards.

Initiatives at manufacturing sites

The Annaka Plant features a centralized grinding fluid treatment room that centrally manages the grinding fluid used in multiple large grinding machines installed within a constant-temperature booth, as well as a silicon fluid treatment system that processes waste liquid generated from cleanrooms used for semiconductor device testing.

Additionally, the newly established foundry at our Thai plant was designed with the goal of becoming a clean foundry.It incorporates comprehensive environmental equipment, including dust and gas collection systems and foundry sand recovery and reuse, enabling a sustainable production system.

We have implemented environmental equipment that thoroughly addresses dust and gas collection, as well as foundry sand recovery and reuse, thereby achieving a sustainable production system.

Centralized coolant fluid management system

(Annaka Factory)

latest environmental facilities

(Thai Factory)

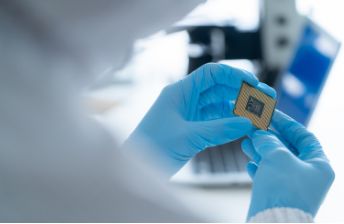

Relation with the end product

Abrasive processing is an important role as one of the backbone processing technology to support the IT ,

digital consumer electronics, automotive and semiconductor industry.

1. Si Wafer

Demand for Data Center and AI semiconductor is increasing.

ICs are equipped in Servers for Data Center, mobiles and electric viechles.

Okamoto has high market share in the polishing machines for Wafer material manufacturers and Grinders for device manufacturers.

2. Transmission gear

Precision grinding can reduce the gear noise from the automotive transmission gear.

It increase the quietness, and improves the fuel efficiency.

Also Okamoto Koki Co., Ltd. manufacture and sale of the gear.

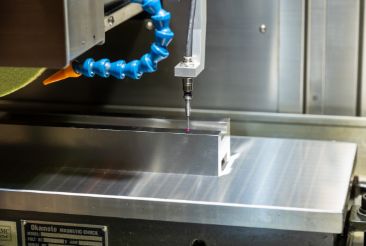

3. Ultra thin and Narrow pitch connector

Mobile phones are becoming thinner and lighter while also processing larger amounts of information, so connectors used are becoming increasingly low-profile and have narrower pitches.

Okamoto’s fine forming grinding machine with linear motor drive is able to finish grinding of mere 0.05 mm fine carbide punches without any warpage.

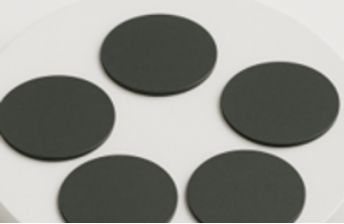

4. Ceramics for the Semiconductor Industry

Ceramics are used in semiconductor manufacturing processes.

Ceramics possess properties such as heat resistance, wear resistance, and electrical insulation, and their demand is increasing alongside the demand for semiconductors.

Our surface grinding machines and rotary surface grinding machines have a proven track record in machining brittle materials such as ceramics.

5. Bearing

Automobile, machinery and Airplane are using bearing as functional components in rotation unit.

Our internal grinder, cylindrical grinder, rotary surface grinding machine are also active in this field.