Series Lineup

[Plain Type] Processable Diameter × Center Distance

OGM225NCⅢ 200×250mm

OGM250NCⅢ 200×500mm

OGM330NCⅢ 300×300mm

OGM350NCⅢ 300×500mm

OGM390NCⅢ 300×900mm

OGM3150NCⅢ 300×1,500mm

[Universal Type] Processable Diameter × Center Distance

OGM225UNCⅢ 200×250mm

OGM250UNCⅢ 200×500mm

OGM330UNCⅢ 300×300mm

OGM350UNCⅢ 300×500mm

OGM390UNCⅢ 300×900mm

OGM3150UNCⅢ 300×1,500mm

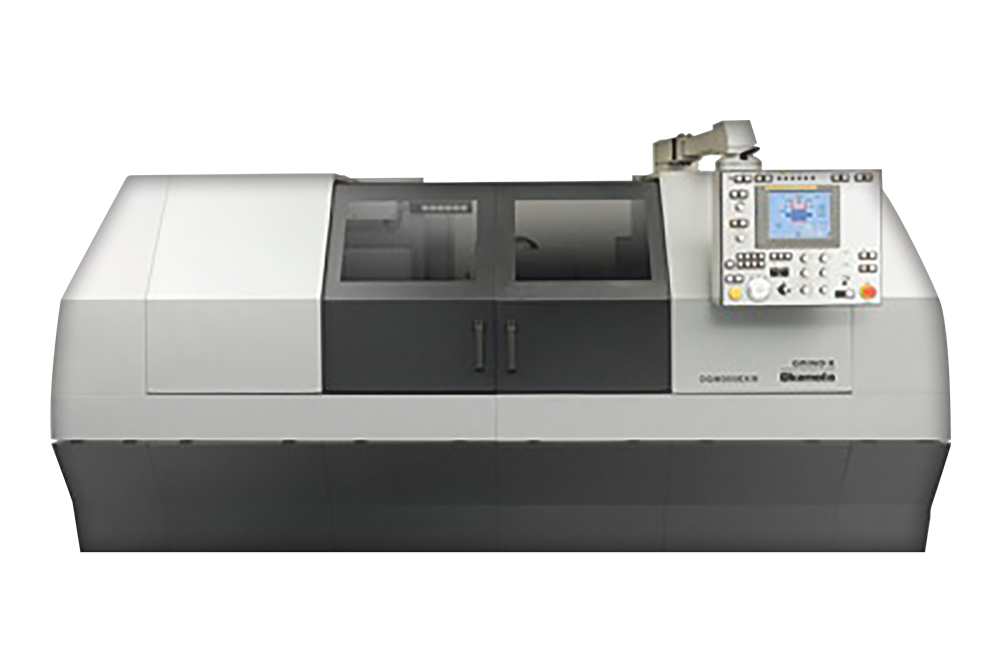

Concept

Simplify grinding cycles for contouring and complex shape machining with simultaneous dual-axis control

Feature

・Features automatic machining data setting (simply input abrasive grit size and width, then workpiece nominal diameter to automatically generate optimal grinding and dressing conditions), enabling easier grinding completion via text-less touch panels and text-free displays.

・Automatically calculates base dressing and machining conditions from grinding wheel information, workpiece dimensions, and overall length data.

・Standard equipment includes an AC servo motor for the machining spindle, an AC spindle motor for the grinding wheel spindle, and scale feedback for the feed axis.

・Features a fully enclosed cover as standard to stabilize machining conditions and the environment.

・For punch grinding of cold forging dies and contouring machining, the machine must accurately synchronize simultaneous dual-axis commands, and software simplifying programming is required. Addressing this, OKAMOTO offers its proprietary EDELAC Win as an option.